Under the slogan “transparency, speed & cost”, KACO new energy GmbH started the project to improve customer service in 2018. With the help of a customer portal, the inverter manufacturer is able to map service requests in a centralized manner. Enriched with data from the ECC system, all relevant information on the components used can be viewed there at any time.

The triad of transparency, speed and cost also formed the guideline for the coordination of the worldwide service partners, which KACO new energy successfully implemented this year. With the introduction of the service partner portal, service partners around the world can be specifically entrusted with a service order on the basis of information from the customer portal. All steps of the service life cycle converge on a single platform – from order creation by the customer or customer service to processing by the service partner and invoicing by KACO new energy.

C4C as the central link

The CRM system C4C - Cloud for Customer of SAP is the central component for the realization of the service partner portal. Relevant ERP data and the tickets from the customer portal are available there. The service partner portal also integrates seamlessly into C4C.

Using standardized service requests, all data collected in the service partner portal is stored in C4C and automatically assigned to the ticket that was previously created in C4C by customer service or with the help of the customer portal. C4C acts as the link between the service partner portal and the customer portal.

Service partner portal in Fiori design

The starting point for the service partner portal is the creation of a service ticket and its assignment to a corresponding service partner.

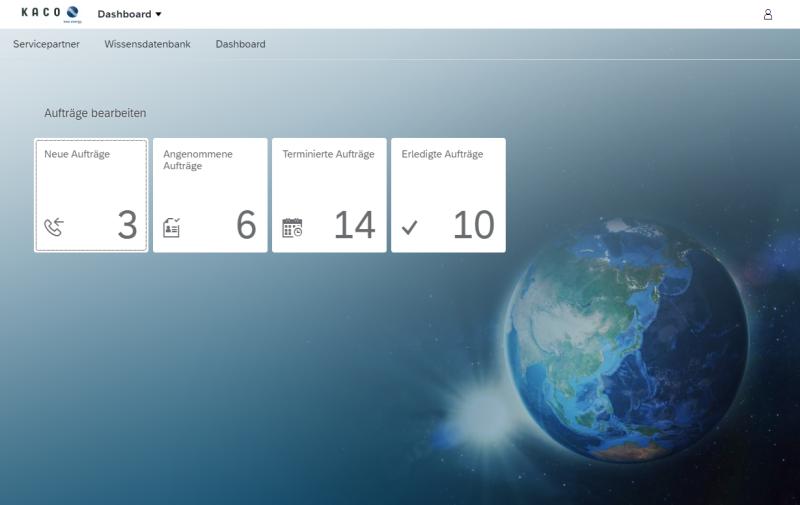

Overview of service requests in the Fiori launchpad from the perspective of the service partner

All new service tickets assigned to the service partner land in the inbox of the service partner portal, which is displayed as a tile on the Fiori launchpad. The service partner can view relevant information and evaluate whether the order is relevant and profitable.

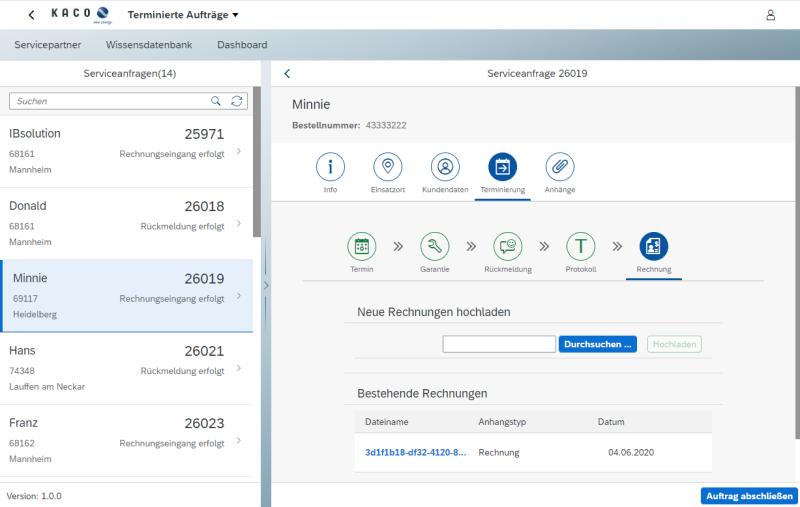

If the service partner accepts the order, a multi-level process of order processing starts. It includes the following aspects:

- Scheduling of the service execution

- Warranty check by the service partner

- Material selection for the execution of the service measure

- Comments on service processing

- Invoicing by the service partner to KACO new energy

When the ticket is completed in the service partner portal, the invoice is also booked in the ECC and the service assignment is invoiced to the customer if necessary.

Mapping of the service process as Fiori app in the portal

The path to service excellence

With its IT ecosystem, KACO new energy has realised a maximum degree of automation. The service partner portal represents a further step on the way to the desired service excellence. The various modules interact seamlessly and pave the way to highly efficient service processes and full cost and service transparency.

In the future, KACO new energy plans to implement predictive maintenance based on machine learning. The company is currently in the process of integrating its inverters into the internet of things (IoT). In the future, each device will have a digital twin.

This virtual image permanently provides live data on its status. Using the parameters, it will be possible to detect at an early stage if errors occur and, for example, a component needs to be replaced. If a repair is necessary, one of the approximately 70 service partners worldwide is automatically commissioned – via the recently implemented service partner portal, of course.

![IBacademy_Logo_blau[496] IBacademy_Logo_blau[496]](https://www.ibsolution.com/hs-fs/hubfs/IBacademy_Logo_blau%5B496%5D.jpg?width=200&name=IBacademy_Logo_blau%5B496%5D.jpg)